Home > Gas Springs > Adjustable Force Tension Gas Springs

Ameritool Adjustable Force Tension Springs are made from 316 stainless steel. Just like the adjustable force gas springs the pressure on these can be reduced down by the user with no tools required. The force on these springs pulls the piston rod inward, operating in the opposite direction of standard gas springs. Great for use on doors, lids, hatches and hoods that need to stay closed or would use assistance while closing. In its relaxed state, the spring is compressed, you must pull to extend.

Key Features:

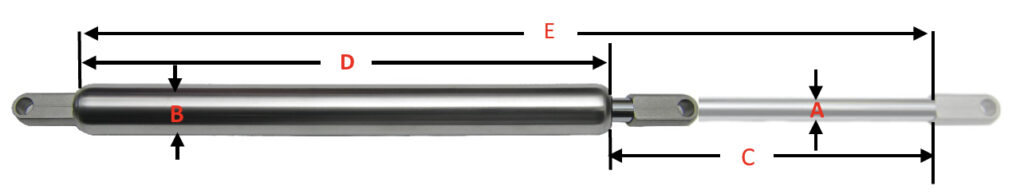

The Guard Tube accessory protects the piston rod from damage due to incidental impacts. This accessory adds 0.1 inches to the extended length of the gas springs, please review the “E” dimension. To order add “08” to the end of your ordering number.

| SKU | Rod Diameter (A) | Body Diameter (B) | Stroke (C) | Compressed Length (D) | Extended Length (E) | Min Max Lifting Force – # (N) |

|---|---|---|---|---|---|---|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

2.25 (57.15)

|

Compressed Length (D)

5.9 (149.86)

|

Extended Length (E)

8.15 (207.01)

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

4.25 (107.95)

|

Compressed Length (D)

7.9 (200.66)

|

Extended Length (E)

12.15 (308.61)

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

6.25 (158.75)

|

Compressed Length (D)

9.9 (251.46)

|

Extended Length (E)

16.15 (410.21)

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

8.25 (290.55)

|

Compressed Length (D)

11.9 (302.26)

|

Extended Length (E)

20.15 (511.81)

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

10.25 (260.35)

|

Compressed Length (D)

13.9 (353.06)

|

Extended Length (E)

24.15 (613.41)

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

12.25 (311.15)

|

Compressed Length (D)

15.9 (403.86)

|

Extended Length (E)

28.15 (75.01)

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

14.25 (361.95)

|

Compressed Length (D)

17.9 (454.66)

|

Extended Length (E)

32.15 (816.61

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

16.25 (412.75)

|

Compressed Length (D)

19.9 (505.46)

|

Extended Length (E)

36.15 (918.21)

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

20.25 (514.35)

|

Compressed Length (D)

23.9 (607.06)

|

Extended Length (E)

44.15 (1121.41)

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

|

SKU

|

Rod Diameter (A)

0.562 (14.3)

|

Body Diameter (B)

1.165 (29.6)

|

Stroke (C)

24.25 (615.95)

|

Compressed Length (D)

27.9 (708.66)

|

Extended Length (E)

52.15 (1324.61)

|

Min Max Lifting Force – # (N)

25-350 (111-1557)

|

Notes:

Fixed Force Tension Springs are designed for smaller, lighter applications. With forces ranging from 35# to 85#

We can make custom designed springs, contact us for design assistance.